Description of the condensation nuclei counter (CNC)

This information (and the figure) come from TSI's website.

CNC Photos

Construction Schematic for rack-mounted CNC box

General Operation

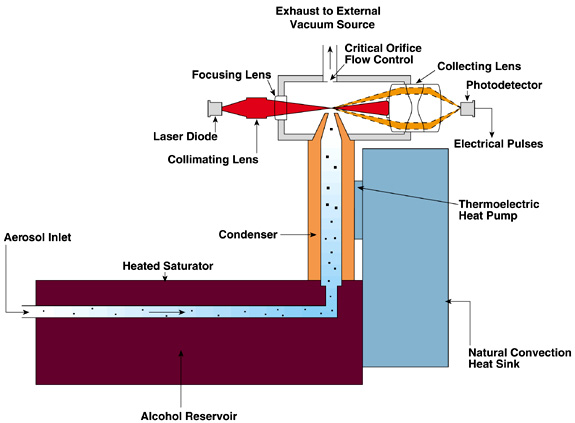

During operation the CNC causes its operating fluid (e.g., butanol or water) to condense onto particles in the sample flow, creating aerosol droplets large enough to be detected efficiently using a light-scattering technique. Upon entering the CNC, the sample passes through a saturation block where operating fluid evaporates into the sample stream, saturating the flow with vapor. The sample then passes into a vertical condenser tube cooled by a thermoelectric heat pump. Here the alcohol supersaturates and condenses onto virtually all particles with diameter greater than 0.01 um, regardless of particle composition. Droplets leaving the condenser tube pass one at a time through a single particle counting optical detector. The pulse of light scattered by a drop traversing the beam is collected and focused onto a photodetector and transformed into an electrical signal. Different CNCs have different minimum cut size (i.e., smallest diameter of particle that can be counted).

| Model Number | Lower Cut Size | Working Fluid |

|---|---|---|

| TSI#3010 | Diameter > 10nm | Butanol |

| TSI#3022A | Diameter > 7nm | Butanol |

| TSI#3760 | Diameter > 14nm | Butanol |

| TSI#3775 | Diameter > 4nm | Butanol |

| TSI#3781 | Diameter > 6nm | Water |

| Brechtel#1710 | Diameter > 6nm | Butanol |

| Aerosol Devices Magic 200 | Diameter > 5nm | Water |

| Aerosol Devices Magic 250 | Diameter > 7nm | Water |

CNC Schematic

CNC Schematic